RAISED ACCESS FLOORING FINISH OPTIONS

Dawn Modular Floor has assembled a comprehensive array of floor finishes, some of which have been selected purely for their exceptional durability and beauty.

For many years, Dawn Modular Floor has been providing specialized and high quality flooring products to architects, designers, contractors, distributors and installers. Dawn Modular Floor offers a flooring finish to satisfy every aesthetic requirement.

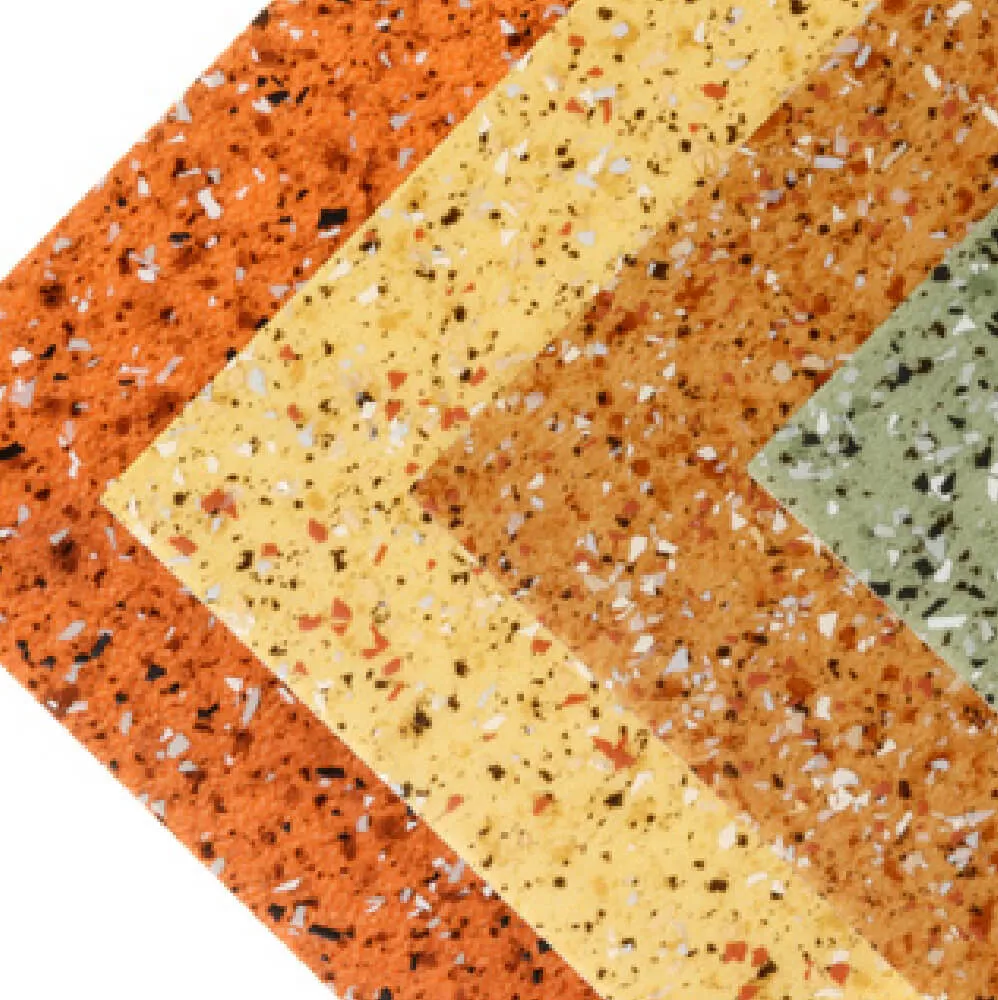

Dawn is offering HPL(High Pressure Laminate), PVC Finish, Rubber, Timber, Granite, Marble, Porcelain, Terrazzo, LVT and Carpet to our worldwide clients.

Description

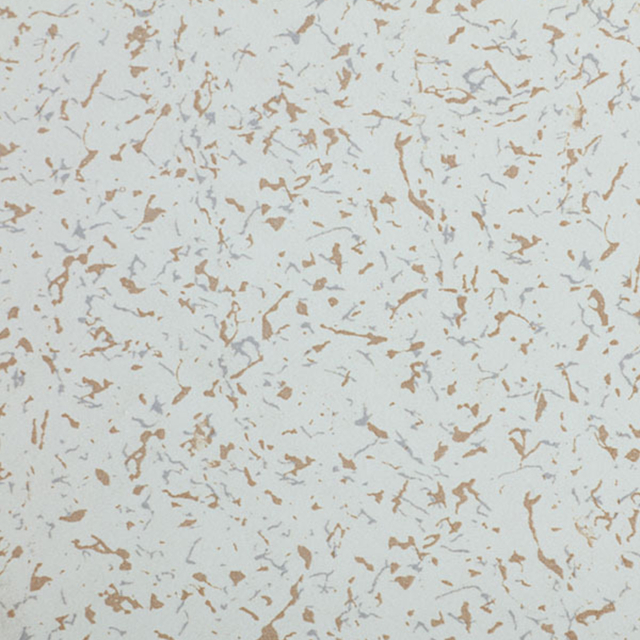

ANTI-STATIC HPL(HIGH PRESSURE LAMINATE)

Laminate is a one piece tile (600x600mm,24” x 24”), and unlike vinyl, will provide a uniform finish with no joints. HPL has the advantage of not requiring wax or maintenance that could produce static problems in the data center.

| Properties | NEMA Test Method | NEMA Standard | Dawn Laminate Results |

| Electrical Resistance | NFPA 99 | – | 1.0×106– 2.0×1010 |

| Stain Resistance | 3.4 | No Effect | No Effect |

| Boiling Water Resistance | 3.5 | No Effect | No Effect |

| High Temperature Resistance | 3.6 | Slight Effect | No Effect |

| Wear Resistance | 3.13 | 3000 cycles/min. | 3000+ |

| Scuff Resistance | 3.16 | No Effect | No Effect |

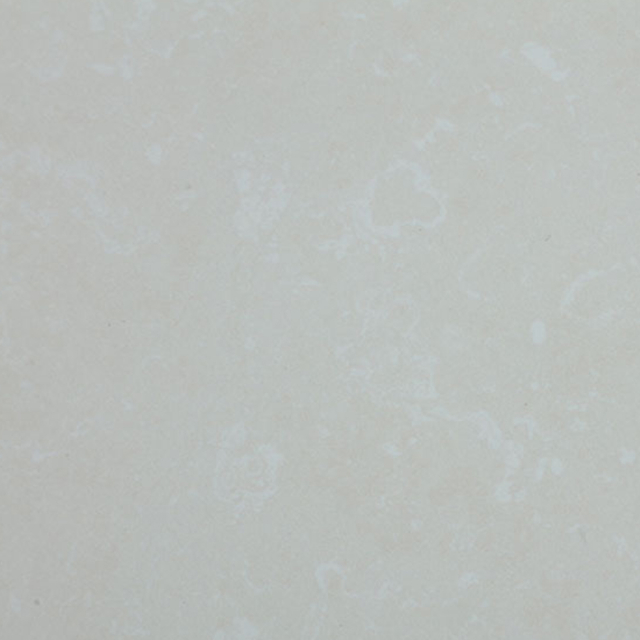

PVC FINISH (CONDUCTIVE & STATIC DISSIPATIVE)

The use of PVC conductive or static dissipative floor covering checks the influence of electrostatic charges in the sensitive work places. The effects of electrostatic influence are very serious, andmany of the incidents include damage to integrated circuits in semiconductor production and lossof valuable data from malfunction of computer equipment caused directly by a buildup of staticelectricity.

There are also some cases of inadvertent ignition of inflammable and explosive substances causedby static discharge.

When two objects with electrostatic charge come into contact or friction, electron movement occurs with electricfication to positive and negative poles which are stationary at the pints of mutualcontact, a direct action against these pints will cause instantaneous electric discharge, the resultbeing damage to products, pollution or malfunction. Because of this, both UL and NFPA strongly recommend the use of conductive floor coverings.

| Performance | Conductive | Static Dissipative |

| Resistance: point to ground | 2.5×104 to 106Ω | 106 to 108 Ω |

| Resistance: point to point | 2.5×104 to 106 to 106Ω | |

| Static decay | 5000 to 0 volts in < 0.01 sec. | 5000 to 0 volts in < 0.2 sec. |

PORCELAIN TILE

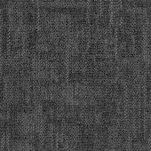

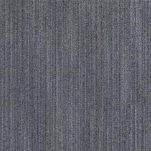

CARPET TILE

| Specification | Details | Specification | Details |

| Structure Type | Tufted loop pile structure | Backing | Eco-friendly PE backing |

| Surface Fiber | 100% Nylon (including antistatic fiber) | Flame Retardance | B1 |

| Dyeing Method | Solution dyeing | Rubbing Color Fastness | Level 4-5 |

| Machine Gauge | 1/12 | Sunlight Color Fastness | Level 5-6 |

| Pile Height | 4±0.5mm | Antibacterial Properties | Antibacterial, Anti-mite, Inhibits Bacteria, Mold, Fungi |

| Size | 50cm×50cm / 60cmx60cm | Environmental Compliance | U.S. CRI+ Advanced Environmental Certification |

| Primary Backing | Polyester spunbond non-woven fabric | Antistatic Performance Index | Permanent Antistatic |

| Surface | Stain-Resistant Treatment |

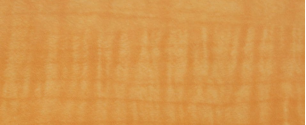

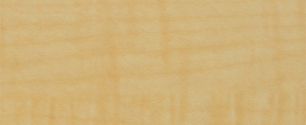

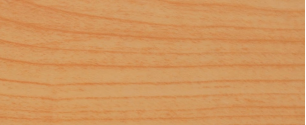

TIMBER TILE

RUBBER TILE

| Test | Average Results |

| Length & Width Size Deviation | ±0.1% |

| Diagonal Corners Squareness Deviation | ≥ 0.008”(0.20 mm) |

| Hardness Shore “A” Durometer | > 85 |

| Tensile-Strength | > 1450 psi (10 Mpa) |

| Bending Resistance (3/4″ metal rod) | No Effect |

| Peeling Strength | ≥ 5620 lbf/ln (25 kN/mm) |

| Wear Resistance (mm/5N) Roller Type | ≤ 150 |

| Thermal Stability (dimensional change) | ≤ ±0.4% |

| Fire Resistance | Yes |

| Resistance to Cigarette Burns | Third Degree |

| Resistance to Chemicals (carbon black ink) | No Visible Change |

| Electrical Properties Volume Resistance | ≥ 1010Q |

| Light Resistance | Third Degree |

| Brittleness Temperature | ≤ 5° F(-15° C) |

| Indentation Residual level | ≤ 0.010″(0.25 mm) |